Continental introduces EcoVero™

The environmental awareness of consumers has been growing steadily over the past decade. More and more people are driven to be more conscious about their buying power and the impact that their spend has on the environment. Textile consumption is expected to double by 2025, and the industry is looking for more sustainable solutions with minimal Eco-footprint for the future of fast-fashion. Achieving this low environmental impact requires developing Eco-friendly raw materials and sustainable manufacturing processes.

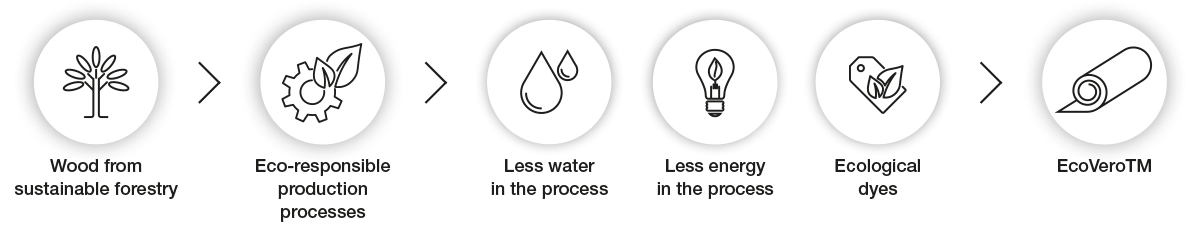

LENZING™ addressed this untapped market demand for more sustainable Viscose by launching ECOVERO™ fibres which have set a new standard based on three key pillars: the use of FSC/PEFC certified wood sources, an ecological production process (significantly lower emissions and water impact) and full supply chain transparency by allowing the fibres to be fully identifiable in the final product. In an age where textile consumption is at an all-time high, LENZING™ ECOVERO™ fibres are contributing to a cleaner and more responsible environment.

The new standard in Eco-responsible viscose.

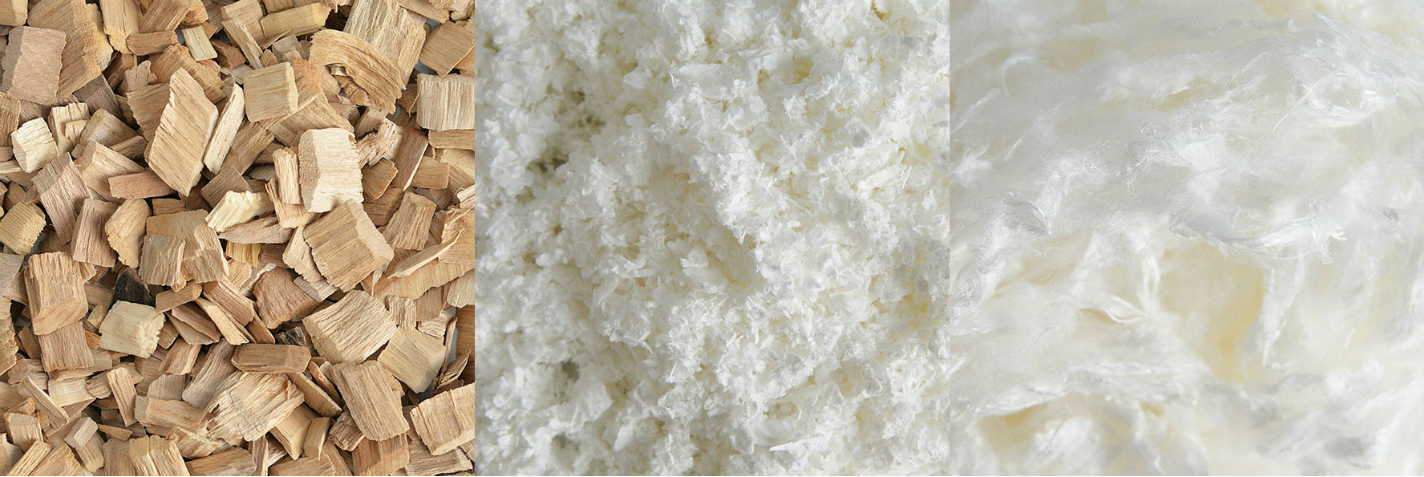

Traditional Viscose is an artificially produced cellulose fibre which is attained through the chemical treatment of wood chips, which is typically sourced from threatened rain-forests and irrigation-intensive mono-cultures, contributing to the global deforestation crisis and resulting in toxic harmful effects to humans and the planet.

ECOVERO™ fibres are made from wood pulp, a natural and renewable raw material. The wood is sourced from sustainable forestry plantations which are 100% certified by industry leading associations such as the Forest Stewardship Council (FSC). LENZING™ has a comprehensive wood sourcing policy which goes above and beyond the call of duty to ensure that only the most sustainable wood sources are used for Viscose production.

The manufacturing of LENZING™ ECOVERO™ fibres generate up to 50% lower emissions and water impact compared to traditionally sourced Viscose. CO2 emissions and fossil fuel resource usage are cut by half in comparison to the industry average. Unlike artificial fibres, the fabric is made from 100% renewable sources which makes the fibre fully biodegradable too.

A special manufacturing system enables LENZING™ ECOVERO™ branded viscose fibres to be identified in the final product, even after long textile processing and conversion steps through the value chain. This allows us to feel fully assured that we are incorporating only eco-friendly viscose into our product.

"With this special identification technology for ECOVERO™ fibres, we are supporting the trend in the fashion industry towards greater transparency. It is becoming increasingly important to know where the products come from and which path they have covered." Robert Van De Kerkhof, Chief Commercial Officer explains.

This unique identification technology is very important for both manufacturers and brands because it supports the trend towards greater transparency and reassures the consumers of their Eco-friendly choices. The branded Viscose fibres are manufactured in Lenzing, Austria and Nanjing, China. Both production locations comply with the stringent guidelines of the EU Eco label. This label of environmental excellence is only awarded to products and services which have a significantly lower environmental impact throughout their life-cycle, from raw material extraction to production, distribution and disposal.

Conventional Viscose VS LENZING™ ECOVERO™ Viscose

What is wrong with conventional viscose?

- The wood is often sourced from threatened rain-forests.

- The raw material is shipped globally causing huge amounts of CO2 emissions.

- Toxic hydrogen sulphide and carbon disulphide are used to break down the wood. In most cases these gases leak and cause damage to the environment.

- A huge amount of energy and water is required during production.

- In most cases only 30% of the raw material is used, with the other 70% being thrown away.

What makes ECOVERO™ a better choice?

- LENZING™ only use FSC and PEFC certified wood from sustainable forestry plantations.

- The wood is sourced locally which cuts CO2 emissions by 50%.

- A closed cycle process means that all water and chemicals used during the production process are recycled and used again, resulting in a 0% pollution impact.

- Only the clean cooling water leaves the cycle, resulting in 50% less energy and water consumption.